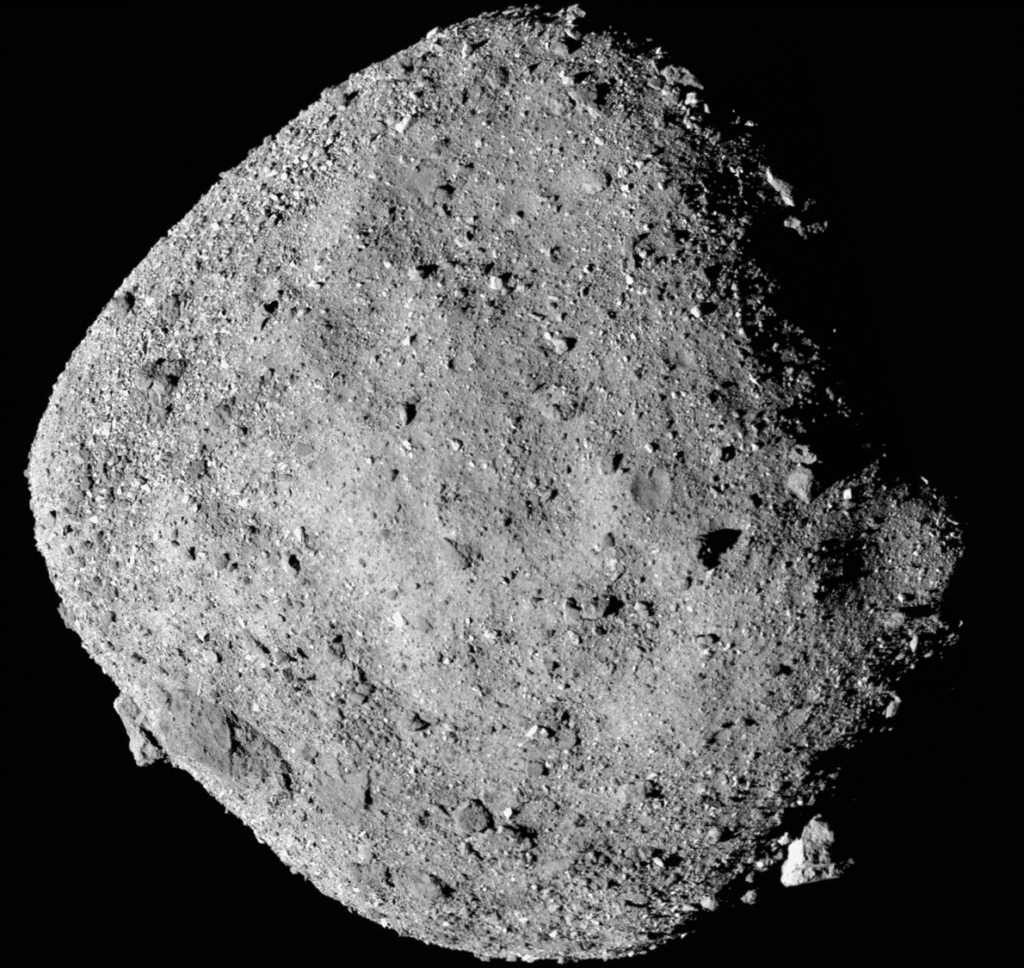

Ever try opening a stubborn jar, but you don’t have a rubber grip handy? NASA scientists have a similar, but far more pressing issue on their hands. The space agency’s OSIRIS-REx mission successfully collected rocks and dust, called regolith, from the surface of asteroid Bennu in 2020. The spacecraft returned to Earth with its precious cargo in September 2023, but scientists are now facing a challenge in opening the sample capsule.

The capsule is equipped with a Touch-and-Go Sample Acquisition Mechanism (TAGSAM) head, which contains the collected regolith. The TAGSAM head is secured with 35 fasteners, but two of these fasteners have proven to be difficult to remove.

This hurdle has led to a pause in accessing the invaluable asteroid samples.

The setback unfolded at NASA’s Johnson Space Center in Houston, where perplexed scientists are strategizing solutions to retrieve the trapped asteroid pieces. “The team has been working to develop and implement new approaches to extract the material inside the head,” NASA explains, “while continuing to keep the sample safe and pristine.”

The Bennu samples are cause for excitement because even amid these challenges, the curation team has already extracted 2.48 ounces (70.3 grams) of extraterrestrial rocks and dust from the sampler hardware. This quantity surpasses NASA’s initial goal of securing at least 60 grams of material from Bennu. It signifies a monumental success as it stands, but there’s more to come.

“And the good news is, there’s still more of NASA’s OSIRIS-REx (Origins, Spectral Interpretation, Resource Identification, and Security–Regolith Explorer) sample to collect,” the team writes.

The materials obtained thus far include particles from the exterior of the sampler head and some bulk samples from inside, retrieved through an opening covered by a mylar flap. Despite the current impasse, additional contents remain inside the sampler head, awaiting extraction once the complication with the fasteners is resolved, promising to further enrich our collection of space samples.

In navigating these unexpected challenges, the team adopted an innovative approach. They managed to secure some samples by retracting the mylar flap and carefully removing accessible material with tweezers or a scoop, tailored to the size of the particles. This meticulous process, along with the initial collection phase, has yielded a mass exceeding the mission’s requirement of 60 grams.

Going forward, the focus for the coming weeks involves crafting and refining a new technique to safely extract the remaining asteroid fragments. Concurrently, the team will process the samples retrieved this week. The OSIRIS-REx science personnel are also poised to characterize the retrieved materials and delve into comprehensive analysis of the bulk sample acquired thus far.

To maintain the purity of the samples for advanced scientific study, all handling and processing occur in a specialized glovebox, an enclosed chamber with a controlled atmosphere. This precaution involves a consistent nitrogen flow to prevent Earth’s atmosphere from contaminating the samples. Consequently, any tools integrated into the extraction solution must be compatible with the glovebox’s confines and uphold the scientific sanctity of the specimens. All procedures will adhere strictly to the clean room’s standards to avoid compromising the samples’ integrity.

In preparation for the next phase, the TAGSAM head, still housing some of the asteroid material, has been removed from the nitrogen stream within the glovebox. It is now securely stored in a transfer container, sealed with an O-ring and enclosed in a Teflon bag, ensuring a stable, nitrogen-rich environment to preserve the sample’s integrity.

This meticulous approach underscores the mission’s dedication to maintaining the pristine nature of the samples, initially gathered from Bennu’s surface in 2020. These samples, consisting of rocks and dust known as regolith, hold untold scientific secrets, potentially offering unprecedented insights into the cosmos’ distant past.

South West News Service writer Dean Murray contributed to this report.

Hammer in a torx bit and use an impact driver (not an impact gun) and it will break loose after 1 or 2 hits.

Righty-Tighty/Lefty Loosy!

If all else fails, get the heavy vice grips out.

Maybe try putting some heat on it.

Always been a fan of space science and exploration.

I hope these rocks are the key to much knowledge.

Thanks to all of you!

Not all are righty tighty lefty Lucy it depends on how they produced it a lot of European bolts are Lefty tighty righty loosen

You damn right Timmy! Whip out the old ground pounding ass hammer!!

Yes, Tim you must be a toolmaker!

Use WD 40

looks to be the case! LoL

If the same stainless alloy was used for bolts AND holes, a condition known as galling has occurred. They actually molecular bond at contact points. Dremel or angle grind the heads off.

Has opening it in a vacuum been tried?

A surgical rated drill, drill bits, and a really good vacuum. Drill out the head of the bolt and use the vacuum to catch any particles or debris. What am I missing here?

Try opening it in a vacuum room.

One successful way I have recently been removing stubborn heavy bolts is to heat the exterior metals which contain the bolt as warm as I can. Then I spray fast acting electronic cleaner spray on the bolt itself freezing the bolt or at least reducing its temperature rapidly compared to the large metal exterior holding the bolt. This has worked several times for me. Good luck. Thank you for your excellent work in space throughout my lifetime.

Have you tried swearing a blue streak and throwing a wrench at it? Space bolts have a reputation of avoiding conflict.

Yeah that’s an Allen head not a Torx head 🤣

Just get a pair of locking pliers in there

Channel Locks or Vise Grips! Does this make me A Rocket Surgeon?🧐

Retighten a few of the bolts that definitely weren’t stubborn. Extract the two stubborn ones with the additional PSI removed. Then back out the initial ones.

Reinstall some of the other screws it will take some of the pressure off the o ring. They probably tighten the screws in a star pattern. Before. They should have reversed loosen the screws. Because them screws they are having trouble with are side by side.

And they want to send ppl to Mars?? Lol

I read all these suggestions and can’t help but think that actual rocket scientist have already tried these and more. As far as using heat, bet that’s not your typical steel. It survived reentry into our atmosphere

Wow the Dunning-Kruger effect is strong in these comments. Just leave it to the experts guys, there are considerations we would never come up with ourselves, all the simple tricks have either been tried or are not acceptable. Such as a drill or angle grinder or heating them up, how do you not affect the sample if you are spraying metal chunks around or heating up the sample chamber. And no, these fasteners are not the two bolts shown in the pic, look at the caption. They may not even be these bolts or even bolts at all.

Ahhhh get a drill from. Any hardware store select a drill that will cut of the bolt head..and like magic…

Spray the troublesome bolt head with electronic component cooler, thus freezing ( shrinking ) the stud. Then slight inpact should allow for removal.

Drill the heads off

What is wrong they are trying to loose the bolts in the wrong direction?

I agree they want to send people to Mars

Sounds like they need to use the Mac RBRT sockets

Send container up to space station. Have them open it during space walk. A lot less chance of contamination. The space walker divides sample up into smaller samples before returning to earth.

Have you tried running it under hot water?

Short bolts somtimes require 2x the torque to remove.

We had one we used when we didnt want cover removed.

Socket heads strip first.

But

Just drill the center about 1/4 inch and it will easily be removed.

Never did figure out why!

Even stumped our analytical group.

Cut it off with a Dremel.

I worked on repairing and designing parts and tooling for orthopedic powered surgical equipment for 24 years. I’m not sure why the heck they used Allen wrench socket head screws. But to get those out the best course of action is to get a slightly oversized torx bit and sternly tap it in to the allen head and then use either a ratcheting box wrench since they are stuck working in a small enclosure, otherwise the best bet would be to use an impact driver after tapping the torx bit into the head of the fastener. But there are plenty of other tricks to try that wouldn’t interfere with the material from space.

Call Mark Rober. He has a way of locking his ice cream into a container people can’t open.

Well I can get that off for you, but it will cost $150,000.

First problem I see is they recessed a socket head bolt! Anybody that is required to own a toolbox for their job will tell you that’s a bad idea. Otherwise you could just grab it with some knipex pliers and be done with it.

Martian Aliens Welded The Fasteners In Place To Test NASA !!!

TIGHTEN yes tighten the bolts very slightly. Should break them free.

J

Have you tried cursing and throwing a wrench across the room, remember left-hand anger.