Want to build houses on the moon or Mars? Well, you’re going to need extraterrestrial cement. And that’s what researchers from the University of Delaware just made! Researchers successfully converted simulated lunar and Martian soils into geopolymer cement.

“If we’re going to live and work on another planet like Mars or the moon, we need to make concrete. But we can’t take bags of concrete with us — we need to use local resources,” says Norman Wanger, Unidel Robert L. Pigford Chair of Chemical and Biomolecular Engineering at the University of Delaware, in a university release.

Researchers say geopolymers are inorganic polymers formed from aluminosilicate minerals found in common clays. When these clays are mixed with a solvent that has a high pH, like sodium silicate, it dissolves. It frees the aluminum and silicon inside to react with other materials and form new structures, like cement. Researchers say lunar and Martian soils house common clays.

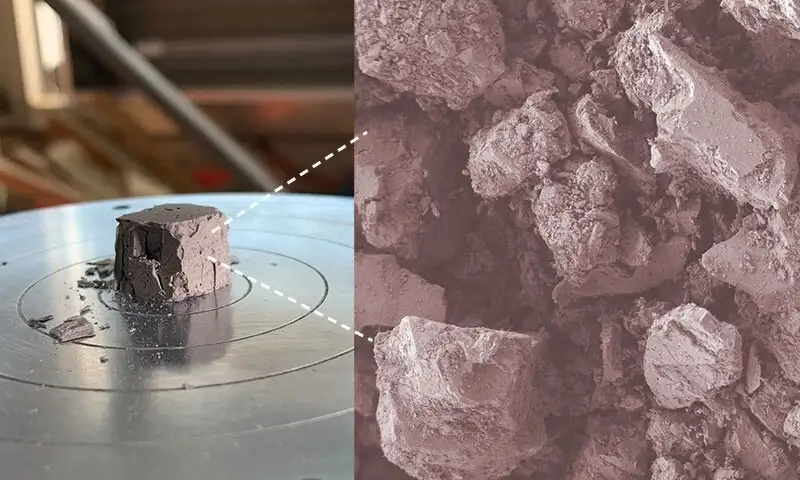

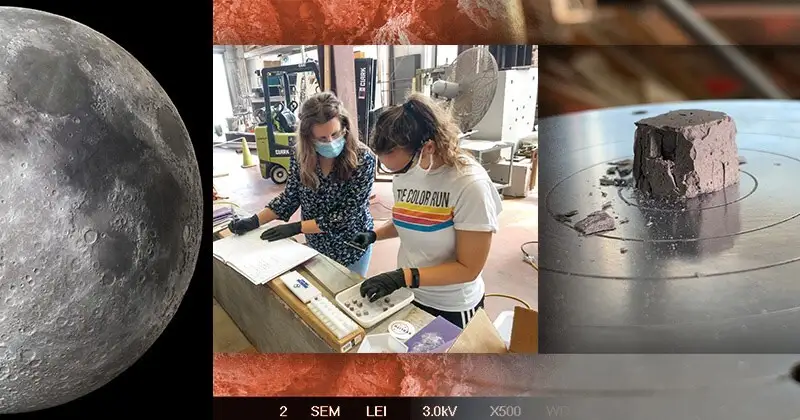

For their study, researchers mixed several simulated soils with sodium silicate then case the geopolymer mixture into ice-cube-like molds and waited for the reaction to occur. Following seven days, researchers measured each cube’s size and weight. They then crushed the cubes to understand how the material behaves under load. Researchers wanted to know if little differences in chemistry between simulated soils affected the material’s strength.

“When a rocket takes off there’s a lot of weight pushing down on the landing pad and the concrete needs to hold, so the material’s compressive strength becomes an important metric,” notes Wagner. “At least on Earth, we were able to make materials in little cubes that had the compressive strength necessary to do the job.”

The scientists also exposed the samples to different environments present in space, including vacuum and low and high temperatures. While being subjected to the vacuum environment, some of the material samples did form cement, while others were only partially successful. Results show that the geopolymer cement’s compressive strength decreased under vacuum, compared to geopolymer cubes cured at room temperature and pressure.

“There’s going to be a tradeoff between whether we need to cast these materials in a pressurized environment to ensure the reaction forms the strongest material or whether can we get away with forming them under vacuum, the normal environment on the moon or Mars, and achieve something that’s good enough,” explains Dr. Jennifer Mills, who earned her doctoral degree in chemical engineering at the University of Delaware and now works at Dow Chemical Company.

When exhibited under temperatures of minus-80 degrees Celsius, the geopolymer materials didn’t react at all. However, researchers found that every moon-like sample got stronger at extreme temperatures, about 600 degrees Celsius. Dr. Mills says this discovery wasn’t surprising, because how the kinetics were hampered at low temperatures.

“The geopolymer bricks became much more brittle when we heated them up, shattering as opposed to becoming compressed or breaking in two,” notes Dr. Mills. “That could be important if the material is going to be subjected to any type of external pressure.”

Researchers say their findings show that chemical composition and particle size may play a critical role in material strength.

The study is published in the journal Advances in Space Research.