The moon’s own surface and a burst of light might be our ticket to a home away from home.

Ever dreamed of setting foot on the moon, staring back at our blue planet? While we’re not offering tickets just yet, a recent forward-thinking study might be bringing us a step closer to making the moon a place we could actually live!

The big challenge of building on the moon is how to get the materials up there. Sending material — or anything for that matter — to space isn’t cheap, of course. The game-changing idea researchers have now? Instead of shipping everything from Earth, why not use the moon’s own dust to build?

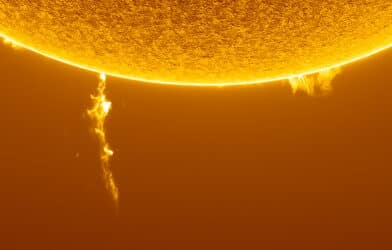

Scientists believe that this moon dust, technically called “lunar regolith,” can be turned into building material with the help of lasers. “The Moon has a wealth of raw materials and energy. By using lasers to melt the lunar regolith, we can create structures directly on the Moon’s surface,” they write in their paper.

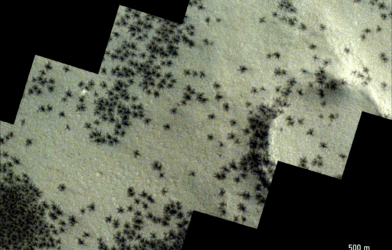

But here’s the twist: the moon’s surface is super dusty. Remember those videos of astronauts bouncing around? Every step kicks up a cloud. This dust isn’t just annoying – it can damage equipment. So, before building moon bases or houses, we need to start with some basics: roads and landing pads.

And it seems the European Space Agency is already on it with a project cheekily named “PAVER”, using lasers on a sort of “moon dust replica” here on Earth to see if this dream can become a reality.

Blast From The Past

While this seems futuristic, the idea actually dates back to 1933! Some bright minds back then thought about using sunlight to melt sand to create roads. Talk about being ahead of their time!

At its core, the new process involves a high-powered laser zapping the lunar dust until it melts, then letting it solidify into new structures. The tests produced three types of materials: one that looks like glass, one that’s crystallized, and a sintered layer (which is a fancy way of saying it’s been compacted).

By manipulating the laser’s power, researchers discovered they could control the depth to which the lunar soil analogue melted. For example, at a power output of 10 kW, they achieved a melting depth of about 20mm in a span of 1200 seconds. And while this may seem like a technical tidbit, it’s crucial for tailoring the technique for different construction needs on the Moon.

Using tools like computed micro-tomography and scanning electron microscopy, the researchers examined the materials they produced. They discovered how dense they are, what kind of tiny pores or cracks they might have, and even got a closer look at the different materials’ microscopic structures.

Knowing all these details is crucial. If we’re dreaming of lunar buildings, they need to be strong! Initial tests on these new materials have been promising, with some samples showing they can withstand a good amount of pressure.

As with all pioneering ventures, the path wasn’t entirely smooth. Initial attempts led to the creation of structures that had a tendency to crack due to thermal shocks. But adversity often leads to innovation. The team reimagined their designs, focusing on geometries that reduced overlaps, thus minimizing these stresses.

However, while the new methods yielded robust paving materials, they came with an unexpected quirk: a glassy top surface. Beautiful, perhaps, but potentially problematic in the harsh conditions of space, where this glassy layer might not withstand sudden temperature changes, especially during events like rocket launches.

The Road to Our Moon Home

With an eye towards the Moon, this research unboxes a multitude of prospects and challenges. The iterative exploration and meticulous analysis of the laser melting process and the subsequent material transformations open a new chapter in understanding how humanity could potentially leverage available resources for construction on the lunar surface. By turning the regolith beneath astronauts’ lunar boots into sturdy, interlocking building blocks, we step ever closer to our dreams of establishing a sustainable presence beyond our terrestrial bounds.

With the ability to achieve varying depths, produce distinct material regions, and demonstrate satisfactory mechanical properties, this method may also be a cornerstone for future lunar infrastructure projects.

The research paper is published in the journal Nature Astronomy.

So, the next time you look up at the night sky, remember: that pale, glowing orb might just be our next neighborhood. And if we play our cards right, we’ll be building it with lasers and moon dust! 🌙✨

-392x250.png)